Ultrasonic Nondestructive Evaluation (NDE)

Microstructure Determination

- Statistical inversion methods based on analytical models of ultrasonic systems and material systems for microstructural grain size determination

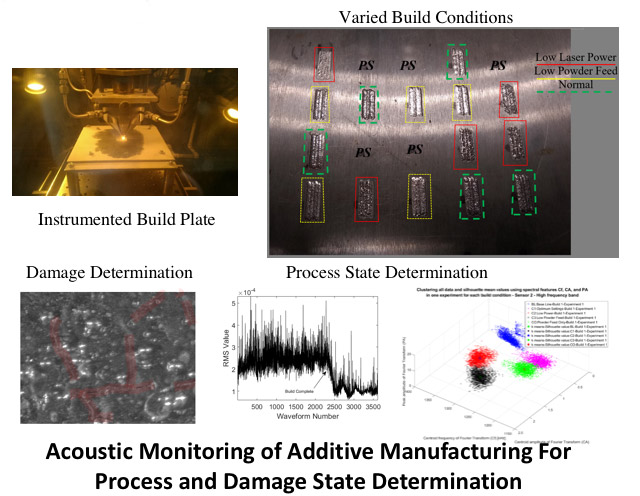

NDE Related to Additive Manufacturing

- Novel methods including acoustic monitoring for process and damage state determination

- Knowledge of methods applied to AM components and their limitations

Flaw Detection and Characterization

- Direct image-based analysis and flaw inversion techniques for metals

- Experience with diffusion bonded metals, microtextured regions (MTRs), porosity, and inclusions

- Additional experience with Ground Penetrating Radar (GPR) and Thermography

Lucas W. Koester

Associate Scientist

lkoester@iastate.edu

Funded Research Sponsors

- Industry/University Cooperative Research Center (CNDE), Honeywell, IHI, & others

Keywords

- Ultrasound, Additive Manufacturing, Microstructure Characterization, Flaw Scattering

Activities and Key References

- Co-Chair, Session on Additive Manufacturing, QNDE 2017-2019

- “NDE for Additive Manufacturing”, Short Course Organizer, QNDE 2018

- Koester, Lucas W., et al. “Nondestructive testing for metal parts fabricated using powder-based additive manufacturing.” Materials Evaluation76.4 (2018): 514-524.

- Taheri, Hossein, et al. “Powder based additive manufacturing-A review of types of defects, generation mechanisms, detection, property evaluation and metrology.” Int. J. Addit. Subtractive Mater. Manuf 1.2 (2017): 172-209.